Scientists have shown a new technology in which bioengineered bacteria can make cost-effective chemicals/polymers from renewable rastlina Viri

lignin is a material which is a constituent of cell wall of all dry land plants. It is the second most abundant natural polymer after cellulose. This material is the only polymer found in plants which is not composed of carbohydrate (sladkorja) monomers. Lignocellulose biopolymers provide shape, stability, strength and rigidity to plants. Lignocellulose biopolymers consist of three main components: cellulose and hemicellulose form a framework in which lignin is incorporated as a kind of connector thus solidifying the cell wall. Cell wall lignification makes plants resistant to wind and pests and helps them from rotting. Lignin is a vast but very underutilized renewable resource of energy. Lignin which represents up to 30 percent of the lignocellulose biomass is an unexploited treasure – at least from a chemical point of view. The chemical industry depends mostly on carbon compounds for creating different products like paint, artificial fibres, fertilizers and most importantly plastic. This industry does use some renewable resources like vegetable oil, starch, cellulose etc but this comprises only 13 percent of all compounds.

Lignin, obetavna alternativa nafti za izdelavo izdelkov

In fact, lignin is the one and only source of renewable on earth that contains a large number of aromatic compounds. This is of importance because aromatic compounds are generally extracted from the non-renewable source petroleum and then are used to produce plastika, paints etc. Thus, the potential of lignin is very high. In comparison to petroleum which is a non-renewable fossil fuel, lignocelluloses are derived from les, straw or Miscanthus which are renewable sources. Lignin can be grown in fields and forests and are generally neutral towards the climate. Lignocelluloses is being considered as a serious alternative to petroleum in past few decades. Petroleum drives the chemical industry at present. Petroleum is a raw material for many basic chemicals which are then used to produce useful products. But petroleum is non-renewable source and is dwindling, therefore focus needs to be on finding renewable sources. This brings lignin into the picture as appears to be a very promising alternative.

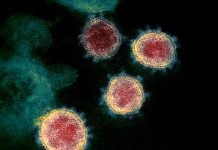

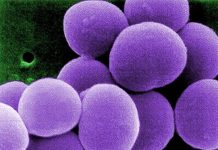

Lignin je poln visoke energije, vendar je pridobivanje te energije zapleten in drag proces, zato se celo proizvaja biogorivo, saj je končni rezultat na splošno zelo drag in ne more ekonomsko nadomestiti trenutno uporabljene "transportne energije". Raziskanih je bilo veliko pristopov za razvoj stroškovno učinkovitih načinov za razgradnjo lignina in njegovo pretvorbo v dragocene kemikalije. Vendar pa je več omejitev omejilo pretvorbo snovi rastline na dotik, kot je lignin, v uporabo kot alternativni vir energije ali celo poskušalo narediti stroškovno učinkovitejšo. Nedavna študija je uspešno razvila bakterije (E. Coli), da delujejo kot učinkovita in produktivna tovarna celic za biokonverzijo. Bakterije zelo hitro rastejo in se množijo ter so sposobni vzdržati ostre industrijske procese. Te informacije so bile združene z razumevanjem naravno razpoložljivih razgradnikov lignina. Delo je bilo objavljeno v Zbornik Nacionalne akademije znanosti ZDA.

The team of researchers led by Dr Seema Singh at the Sandia National Laboratories solved three main problems that are encountered in turning lignin into platform chemicals. The first major hurdle is that bakterije E.Coli generally does not produce the enzymes which are needed for conversion. Scientists tend to solve this problem of making enzymes by adding an “inducer” to the fermentation ring. These inducers are effective but are very expensive and thus do not fit well in the concept of biorefineries. Researchers tried a concept wherein a lignin derived compound like vanilla was used as a substrate as well as an inducer by engineering the bakterije E.Coli. This would bypass the need for an expensive inducer. Though, as the group discovered, vanilla wasn’t a good choice particularly because once lignin breaks down, vanilla is produced in large quantities and it starts inhibiting the function of E.Coli i.e. vanilla starts creating toxicity. But this worked in their favour when they engineered the bakterije. In the new scenario, the very chemical that is toxic to the E.Coli is used to initiate the complex process of “lignin valorisation”. Once vanilla is present, it activates the enzymes and bacteria starts to convert vanillin into catechol, which is the desired chemical. Also, the amount of vanillin never reaches the toxic level as it gets autoregulated in the current system. The third and final problem was of the efficiency. The system of conversion was slow and passive thus researchers looked into more effective transporters from other bacteria and engineered them into E. Coli which then fast tracked the process. Overcoming toxicity and efficiency problems by such innovative solutions can help make the production of biofuel a more economical process. And, removal of an external inducer along with incorporation of auto-regulation can further optimize the biofuel-making process.

Ugotovljeno je, da ima lignin, ko se razgradi, sposobnost zagotoviti ali bolje rečeno "podariti" dragocene kemikalije platforme, ki jih je mogoče nato pretvoriti v najlon, plastiko, farmacevtske izdelke in druge pomembne izdelke, ki so trenutno pridobljeni iz nafte, ki ni -obnovljiv vir energije. Ta študija je pomembna kot korak k raziskovanju in razvoju stroškovno učinkovitih rešitev za biogoriva in bioproizvodnjo. Z uporabo tehnologije bioinženiringa lahko proizvedemo večje količine platformnih kemikalij in več drugih novih končnih izdelkov, ne samo z bakterijsko E.Coli, temveč tudi z drugimi mikrobnimi gostitelji. Prihodnje raziskave avtorjev se bodo osredotočile na prikaz varčne proizvodnje teh izdelkov. Ta raziskava ima velik vpliv na procese pridobivanja energije in širjenje možnosti za zelene izdelke. Avtorji ugotavljajo, da bi morala lignoceluloza v bližnji prihodnosti zagotovo dopolnjevati nafto, če je ne nadomestiti.

***

{Izvirno raziskovalno nalogo lahko preberete s klikom na spodnjo povezavo DOI na seznamu citiranih virov}

Vir (i)

Wu W et al. 2018. K inženiringu E. coli z avtoregulacijskim sistemom za valorizacijo lignina', Zbornik National Academy of Sciences. 115 (12). https://doi.org/10.1073/pnas.1720129115